The Ottawa Hospital was the first Canadian hospital to have an integrated medical 3D printing program for pre-surgical planning and education. Since the arrival of the program, made possible by the generosity of a donor, The Ottawa Hospital has been a leader in innovative advancements in this area. Doctors have been able to harness 3D printing to create detailed anatomical plans before a patient arrives in the operating room, reducing the need for invasive surgery, and ultimately improving outcomes with a significant cost savings. It’s this program, which positions the hospital’s Medical Imaging Department at the forefront of international developments in radiology and is revolutionizing the way surgery is done. It’s this kind of forward thinking that allowed The Ottawa Hospital to be ready when the COVID-19 pandemic arrived in Ottawa, mobilizing innovative 3D printing technology at the hospital, in local companies, and out in the community, to quickly create PPE for front-line workers.

Ready to face the pandemic

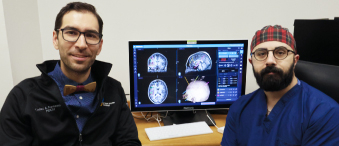

As members of The Ottawa Hospital’s 3D Printing Laboratory watched how COVID-19 was spreading throughout China and Europe, they quickly became aware of how some parts of the world were facing dramatic equipment shortages. That’s when Dr. Adnan Sheikh, Director of the 3D Printing Laboratory, and his team started to think creatively about how they could help their colleagues be better prepared for the pandemic.

“I reached out to Dr. David Neilipovitz, Department Head of Critical Care, to offer help and we identified many areas where the 3D Printing Lab would be in the best position to help in case of any shortages,” says Dr. Sheikh.

From that conversation, the 3D printing team started developing several different designs of PPE (Personal Protective Equipment) to help safeguard colleagues who would be caring for patients critically ill from COVID-19.

“We were able to create oxygen tents, goggles, tube connectors, intubation shields, and face shields which are a key piece of equipment,” explains Dr. Sheikh.

These transformational advancements wouldn’t have been possible just five years ago.

“This is an innovative technology. It’s really evolved and it’s changing the way we practice medicine.”

— Dr. Adnan Sheikh

Testing the prototypes

Once the 3D lab began producing pieces of PPE, each one needed to be tested. Dr. Neilipovitz played a key role in testing these designs in advance, allowing The Ottawa Hospital to be innovative during challenging times.

“Thanks to our 3D team, they allowed us to think outside the box and quickly find us solutions to be ready to help our patients.”

— Dr. David Neilipovitz

In fact, Dr. Neilipovitz and his team in the ICU were instrumental in helping the 3D team refine and test prototypes to ensure they were up to the task. A crucial step in the process and one that required patience, expertise, and an open mind.

A perfect example was an intubation shield designed with the help of Leonard Lapensee, an Imaging Technician, who works at the hospital. The ICU team tested this prototype; they modified it and it was later mass-produced. This is now used in the ICU, operating rooms, and emergency rooms.

Dr. David Neilipovitz trying on a prototype mask

The end result which includes a 3D-printed blue valve at the top

Community support takes The Ottawa Hospital to the next level

Once they received the green light for the 3D equipment, The Ottawa Hospital was then able to produce as much quantity as the lab could handle. However, the collaboration went beyond the lab and even the walls of The Ottawa Hospital.

“We knew we had limited resources and were aware that we wouldn’t be able to manufacture and print everything in the lab. So, we prototyped these devices and pushed them out for production at different sites at The Ottawa Hospital. We also reached out to volunteers in the community who had offered to help.”

There was a collaboration with the University of Ottawa Makerspace led by engineering professor Dr. Hanan Anis and her team to help with the design and prototyping process. It didn’t stop there—the community support continued to grow to help produce PPE such as face shields, and even headbands.

A good example of that support was when Ottawa resident Marc Beal stepped forward to lend a hand. “Due to resource constraints, we needed help printing headbands for face shields. Marc and his friends, who have home 3D printers, approached us and printed these headbands for us,” explains Dr. Sheikh.

Marc Beal working at home on his 3D printer

Dr. David Neilipovitz testing an oxygen hood

Another key piece of equipment was the oxygen helmet, which is used with patients who require a constant flow of oxygen. Once again, the 3D lab was able to prototype it. “We tested it and once we were convinced that it would help our patients, we reached out to Darcy Cullum at Ottawa Mould Craft, who was happy to work with us.”

Ultimately, that community support allowed The Ottawa Hospital to ensure staff have the PPE needed to keep both care team members and patients safe during the peak of COVID-19.

The best part of all, notes Dr. Sheikh, is that this all came about organically. “Colleagues helping colleagues—having an open mind and being willing to integrate what we can contribute. That included assessing the gear and testing it out to make it reality. I feel privileged to live in Ottawa; our community support system is the best in the world!”

COVID-19 may have turned the world upside down but it was a forward-thinking donor in 2016, who allowed The Ottawa Hospital to have the technology in place to be ready when our patients needed us most.

“With COVID-19 everything has changed. 3D printing now has a different role in the medical world.”

— Dr. Adnan Sheikh

The Ottawa Hospital is a leading academic health, research, and learning hospital proudly affiliated with the University of Ottawa.